Color coated aluminum plate

Key words:

Color coated aluminum plate

Classification:

- Details

-

Product description

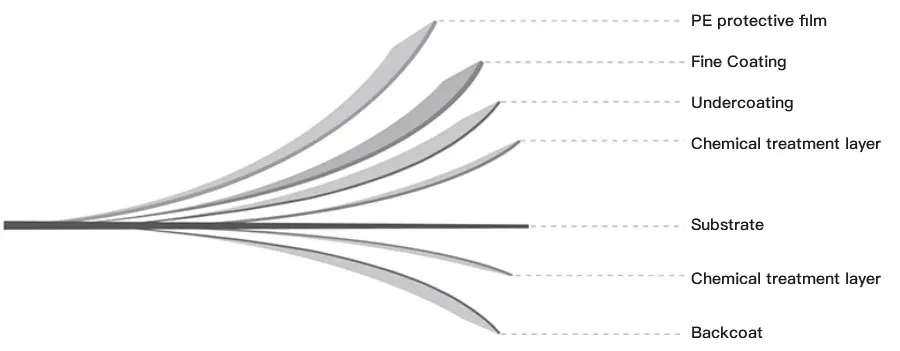

After the light aluminum coil is cleaned, chromed, rolled, baked, etc., the surface of the aluminum coil is coated with various colors of paint, that is, the color-coated aluminum coil. Color aluminum is widely used in honeycomb panels, thermal insulation panels, aluminum curtain walls, shutters, roller shutters, aluminum-magnesium-manganese roofing systems, aluminum ceilings, and household appliances because of its light texture, bright colors, easy processing, and no rust. , downspouts and many other areas.

Rio Tinto's color-coated aluminum coils are mainly from Mingtai, Chuangxin, Weiqiao, Southwest Aluminum, Chinalco and a few other domestic raw material suppliers; the paints used for coating are mainly from Zhengliang, PPG, Becker and Aksu; Rio Tinto color aluminum coating line is specially designed and introduced for color aluminum coating, which is more stable and accurate than the roller coating line converted from color steel line.

With excellent quality and advanced management, our color-coated aluminum coils and applied products have been exported to many countries and regions in Europe, North and South America, Southeast Asia, the Middle East, East and West Africa, etc.

Coated aluminum coils can be simply divided into polyester (PE) coated aluminum coils and fluorocarbon (PVDF) coated aluminum coils due to different processing processes and purposes.

After the aluminum coil is embossed, it also becomes an embossed aluminum coil, with orange peel (stucco) and diamond pattern (diamond). Rio Tinto embossed aluminum coil width can reach 1400mm, thickness can reach 1.2mm;

Because of different uses, they are usually used as roofing materials (aluminum-magnesium-manganese roofing systems), ceiling materials (for aluminum alloy ceilings), home appliance boards (used in the interior and exterior of household appliances, in line with EU Rohs standards), brushed boards ( The surface is brushed) and so on.

Product structure Basic parameters

Basic parametersSubstrate Cold-rolled steel sheet, hot-dip galvanized steel sheet, electro-galvanized steel sheet, etc. Substrate thickness 0.20- 0.8mm

Available sizes Width≤1250mm, length≤5000mm Available for coils Width≤1250mm, single roll weight≤10T, inner diameter of roll is 508mm Achievable effect Product Usage

Product UsageAluminum Manganese Magnesium Roof Sheet

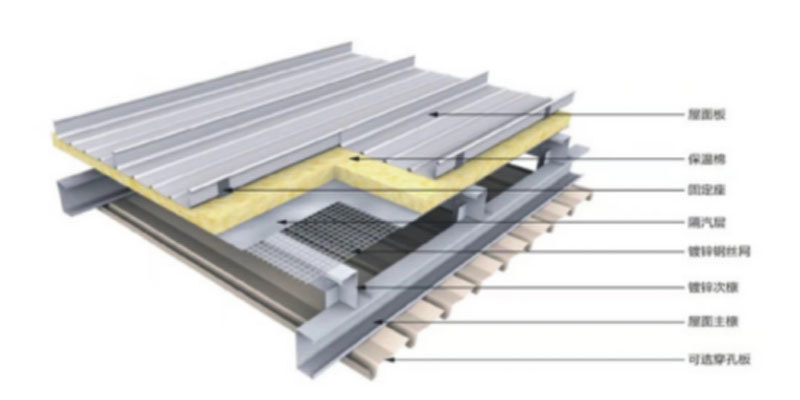

Metal roof panel, the basic material is (aluminum, manganese, magnesium) alloy, grade 3004 (AI Mn Mg), since the aluminum metal roof panel is 0.7~1.2mm thick, the structural strength is moderate, and it is easy to weld and bend, except for standard connections. In addition to technology, exhaust holes, inlets and exits, etc., can be welded on site. At the same time, under different wind pressure conditions, the integrity of the material can be guaranteed, and the standard conforms to the GB3880-97 or ASTM3004 standard, so it is widely used in the maintenance system of the building.

Based on advanced roller coating technology, the production of aluminum-manganese-magnesium roof panels can stand the test of a long time, and the close protection can eliminate the influence of weather and has been established for many centuries. Metal roof panels show their advantages in the design of more special buildings such as low slope, flat roof, curved, arched and hyperbolic roofs.

Rio Tinto's aluminum-magnesium-manganese alloy color-coated aluminum coils are widely used in many landmark buildings such as aircraft terminals and railway stations all over the country. Because of its excellent quality, it is widely praised in the industry.

Typical alloy states are: A3004H24, A3004H26, A3003H24;

Typical thickness range: 0.6mm/0.7mm/0.8mm/0.9mm/1.0mm/1.2mm;

Width: According to customer requirements, it can be cut to any width within 55mm to 1400mm;

Color: Common flash silver, silver gray, bright silver, champagne silver, gray and other thousands of colors.

Aluminum ceiling

Aluminum alloy ceiling (aluminum ceiling) is widely used in airports, station waiting halls, subway stations, commercial buildings, shopping malls, hotels and other entertainment venues and home decoration. It is a relatively modern ideal interior decoration material.

The surface of the aluminum alloy ceiling is treated with polyester roller coating, which is rich in color, light in texture, environmentally friendly, non-polluting; fireproof, moisture-proof, non-discoloring, and easy to clean. The product can be formed at one time, and has many plate shapes, smooth lines, easy assembly and disassembly, easy maintenance, and good appearance.

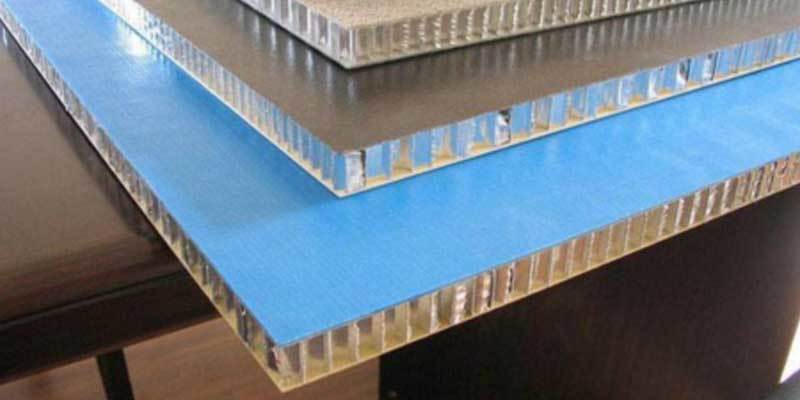

Aluminum coil for composite sheet

The inner and outer layers of the aluminum alloy honeycomb panel are aluminum alloy sheets, and the middle interlayer is a regular hexagonal aluminum foil honeycomb core. Lidao color-coated aluminum coil, the surface can be coated with polyester or fluorocarbon coating according to the color required by customers, and the back is epoxy, which is the first material for manufacturing aluminum honeycomb. Aluminium sheet for rolling shutter door

Rio Tinto anti-scratch (PUPA) color-coated aluminum coil, the surface is coated with polyester anti-scratch paint roller, has a good anti-scratch effect, is the choice of many domestic and foreign aluminum alloy rolling door manufacturers.

Commonly used aluminum alloy grades are: A3105H26, A3003H18; A3005H26, etc.

Conventional thickness: 0.22mm, 0.23mm, 0.25mm, 0.26mm, 0.27mm, 0.4mm, 0.45mm, etc., can be customized according to customer needs;

Conventional width: 127mm, 133mm, 138mm, 187mm, etc., can be cut according to customer needs;

Color: At present, there are dozens of colors such as scratch-resistant white, scratch-resistant black, scratch-resistant beige, scratch-resistant red brown, scratch-resistant gray silver, scratch-resistant champagne silver, etc. for customers to choose, and can also be customized according to the colors provided by customers.

Related Products

Color-coated building materials board

Color-coated building materials board

Color coated purification board

Color coated purification board

Color coated purification board

Color-coated stainless steel plate

Color-coated stainless steel plate

Color-coated stainless steel plate

Message